Laser processing is a new processing method.

Source:网络 Time:2007-07-27 Edit:SunyLaser

Laser embroidery

More than 2/3 of the textile and garment fabric can be used to produce a variety of laser digital patterns. Late of traditional textile fabric production process requires processing grinding flower, pyrograph, embossing and laser sintering spent on this aspect has made convenient, fast, flexible pattern transform, image is clear, three-dimensional sense of strong, can full performance of all kinds of fabric color texture, and calendar long often new advantages. If the combination of hollow craft is a finishing touch, complement each other.

Garment fabrics and garment laser embroidery is suitable for: after finishing the textile fabric finishing processing factory, the fabric deep processing factory, the clothing factory, the surface material and the processing enterprise.

Cowboy image laser flowers

Through numerical control laser irradiation, dye of vaporization of denim fabric surface, thus in a variety of denim fabrics produce will not fade image pattern, gradient, flower shaped, cats should be matte effect, has added a new beautiful fashion denim.

The cowboy spraying laser processing is a new, rich processing profits and market space processing project, very suitable for denim garment factory, washing plant, processing etc. enterprises and individuals cowboy series product value-added deep-processing.

Leather fabric laser marking

Laser technology is widely used in shoes and leather industry. Advantage of laser in various kinds of leather fabric fast carving and hollowing out all kinds of patterns, and the operation is flexible, and will not make the leather surface any deformation, to reflect the color and texture of the leather itself. It has high precision carving, pierced without flash, arbitrary selection of a variety of advantages, for uppers, shoes, leather goods, handbags, luggage, leather clothes, such as processing manufacturers.

Laser engraving is laser devices laser engraving software, artwork input automatic carving practices. At present, laser engraving is the most mature and widely used technology in laser processing. With this technology, any complex graphics can be carved. Carving and does not penetrate the blind grooves carving can be, which carved out of the depth, different textures, with sense of hierarchy and color transition effect all magic pattern. By virtue of these advantages, laser engraving to meet the new trend of international garment processing.

Laser cutting with embroidered cloth

Computer embroidery process, there are two steps is very important, that is, before the cloth embroidered with the cutting and embroidery after cutting. In the traditional processing technology, embroidery before cutting the knife mold machining defects in, easy to produce fabric fringed and machining accuracy by knife mold Limited, specific graphics to processing, knife mold production cycle, high cost, thus restricting the development of embroidered cloth paste. And after the cutting material cutting, mostly used is the way of hot processing, the way and cutting edge gap, the edge of yellow hair hard, difficult to position and so on. Opposite sex figure rely on artificial hand cut, it is easy to loose edge, produce waste, so it is urgent need to have an advanced processing method to replace these two old processing methods.

Laser processing, although it is also a hot processing, but due to the high degree of focus of the laser beam, the light spot is fine, small thermal diffusion zone, so it is very suitable for the cutting of textile fiber fabrics. Specific performance in wide processing range of fabrics, incision smooth without burr, automatic closing, no deformation, graphic through computer random design and output, without knife mold and so on. This makes the laser processing industry recognized as an alternative way.

Laser marking marking with high precision, fast speed, marking a clear, hard, soft, brittle products plane, arc and flying objects of printing a variety of text, symbols, patterns. Laser marking compatible with laser cutting, engraving of the various advantages, can be in the metal and organic polymer chip precision machining, processing small size complex pattern. Print mark has never wear the anti false performance, can be specialized in making cloth label, leather label, metal label, print pattern complex and fine variety of the company logo and LOGO, is the best choice of brand clothing and accessories processing.

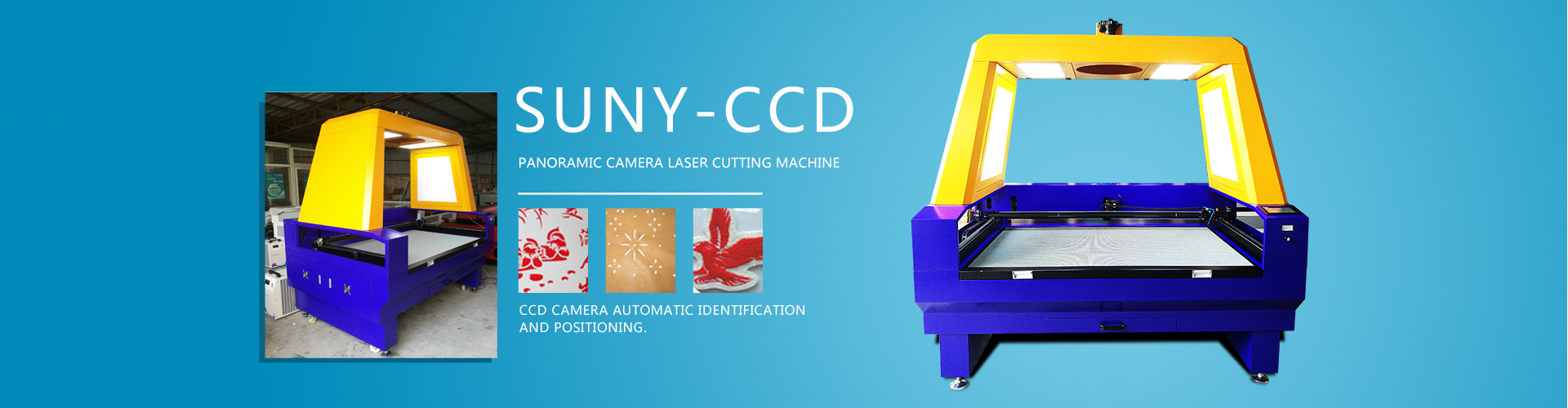

For a long time, trademark cutting edge, embroidery trimming and embroidery patterns punched parquet are a matchup problems. Accurate and efficient cutting is the common expectation of the industry. The existing automatic visual tracking cutting system is a big step forward on the basis of the traditional manual alignment cutting, and can automatically locate and cut the position of the branch points. However, the random deformation of textile products can not be automatically corrected, so it will produce a lot of waste. Now industry enterprises have been successfully developed automatic recognition to find edge cutting system, can according to the organized edge graphics trademarks, automatic generation of cutting path, and accurately by using laser contour cutting. Can also be automatically positioned on the embroidery patterns in the pattern cutting and drilling.

Email

Email MSN

MSN Want

Want QQ

QQ

中文

中文 ENGLISH

ENGLISH